Fluorine-free chemical release agent

Industrial Release Agent (Fluorine-Free, Silicone-Free)

*Fluorine- and Silicone-Free Composition: Complies with strict environmental and electronic industry regulations regarding contaminants.

*High Heat Resistance: Withstands temperatures up to 700 °C, suitable for a variety of thermal press and die-cutting processes.

*Quick Drying: Dries within 60 seconds (depending on heating and ventilation), forming a thin, non-transferring anti-stick layer without contaminating the substrate.

*Excellent Release and Insulation Properties: Ideal for use in precision electronic processing environments.

*Versatile Substrate Compatibility: Suitable for die-cutting base materials such as PET, PI, PE, PVC, foam, and more.

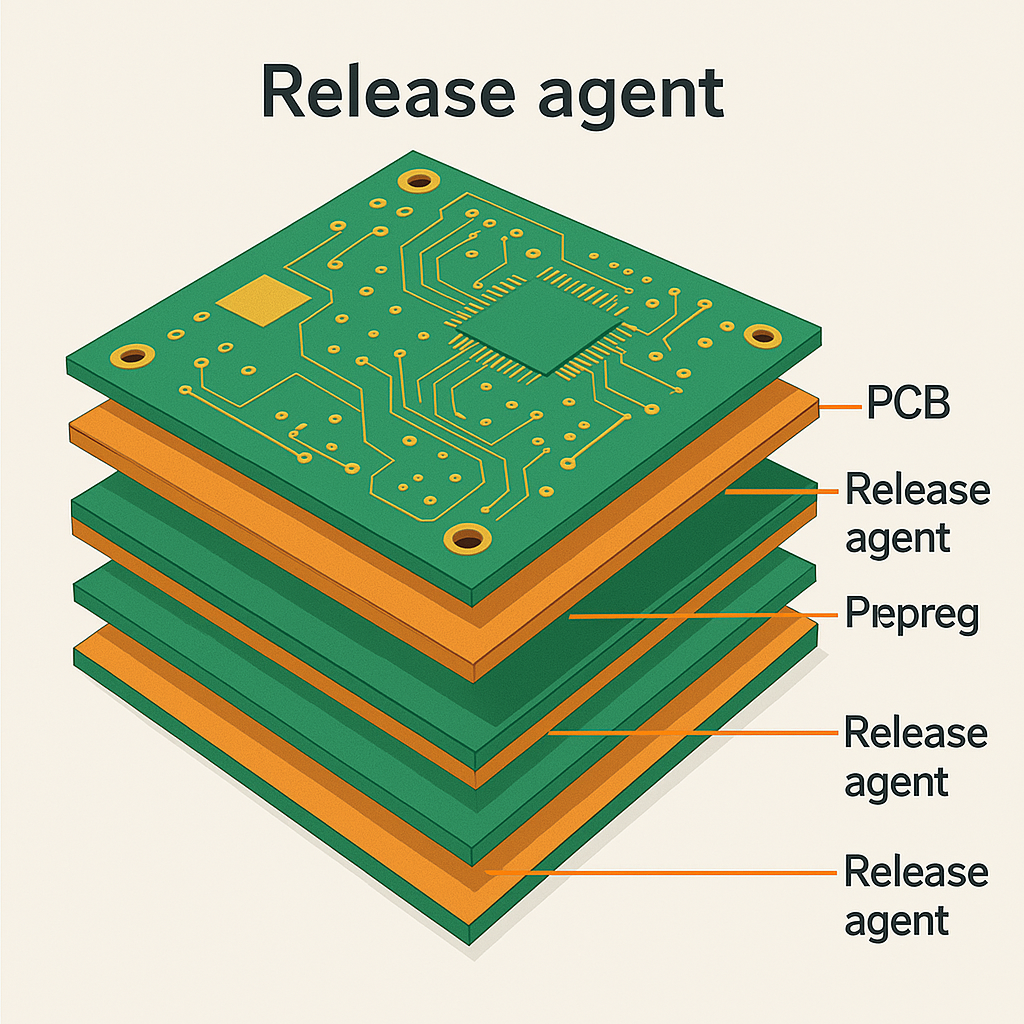

PCB Lamination and Molding Processes: Designed for use in the lamination and molding of multilayer printed circuit boards (PCBs). When applied during high-temperature and high-pressure lamination, this release agent prevents resin adhesion to steel plates or press pads, ensuring smooth demolding and a clean surface finish. In PCB processes involving thermal compression molding, this product provides reliable release and separation, preventing interlayer sticking and press contamination.

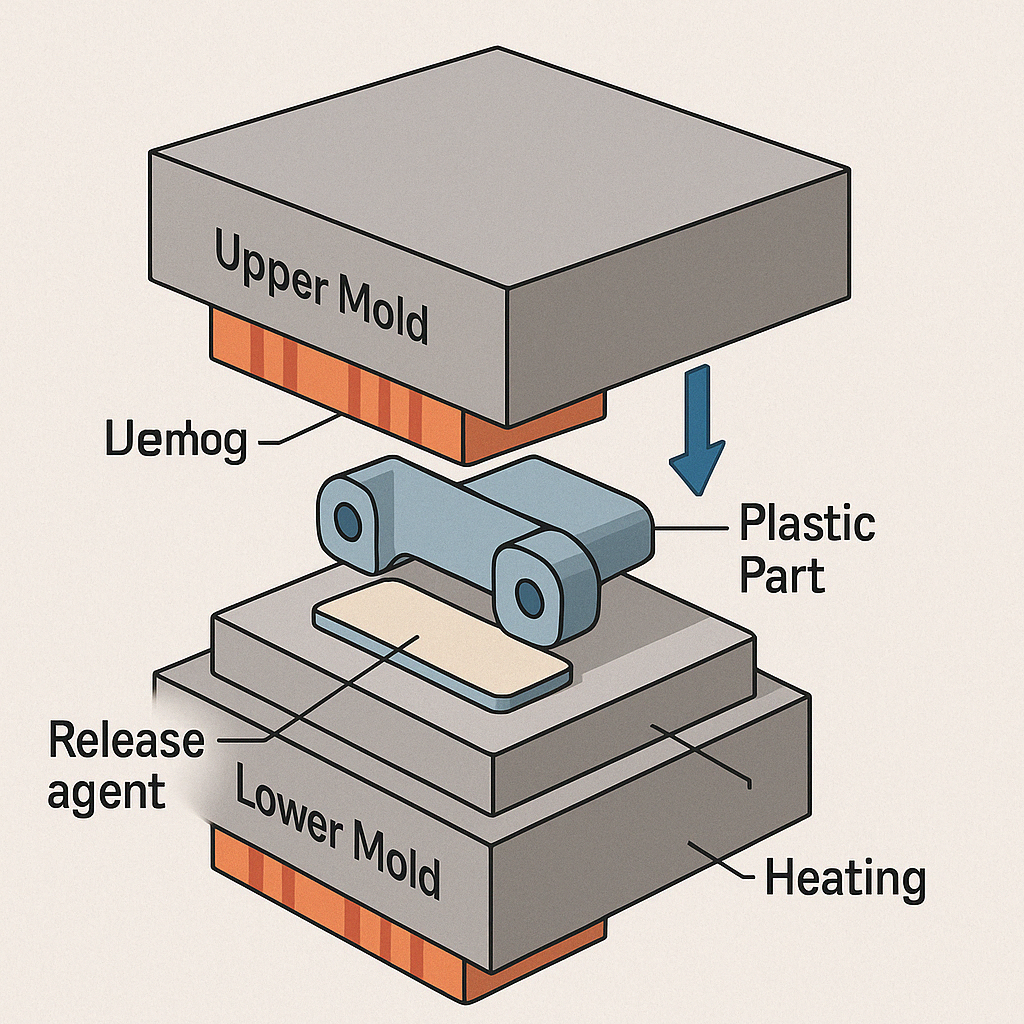

Mold Release for Thermal Compression Molding: Suitable for various high-temperature molding processes such as thermal compression, forging, and high-temperature casting. When applied to metal molds before molding rubber, plastic, or composite materials under high heat, this release agent forms a protective film that reduces friction and adhesion between the mold and the product, enabling easier release. Especially for molds with complex shapes or extended heating cycles, the product’s excellent thermal stability prevents carbonization and failure common with traditional release agents, thereby extending mold life and improving production efficiency.

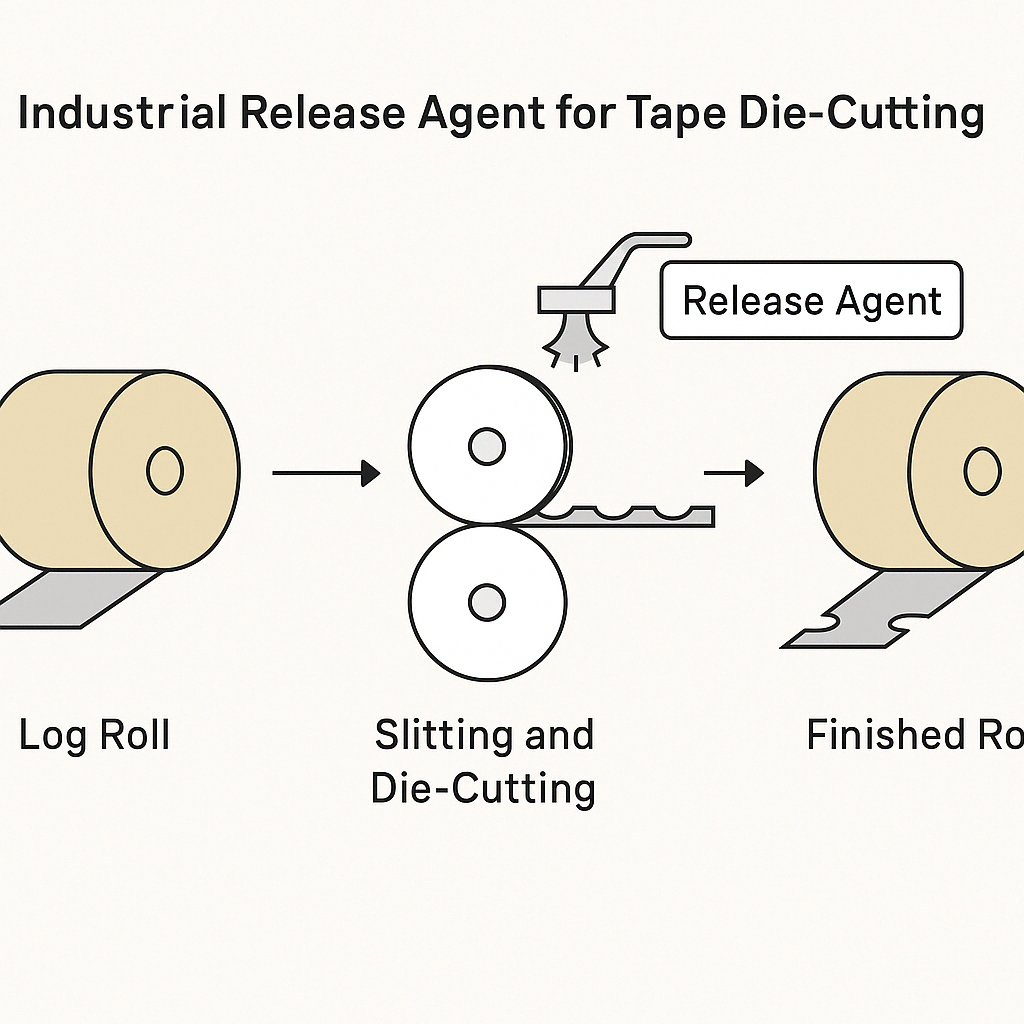

Die-Cutting Release and Anti-Stick Solution for Industrial Tapes: Designed for die-cutting processes involving industrial tapes and adhesive products. When applied to die-cutting blades or tooling surfaces, this release agent effectively prevents adhesive residue from sticking to the tooling. Its silicone-free formulation ensures no silicone oil transfer, preserving the adhesive performance of the tape. Used as a separator, this product helps maintain clean die-cutting equipment, reduces downtime for cleaning, and improves both processing precision and yield.